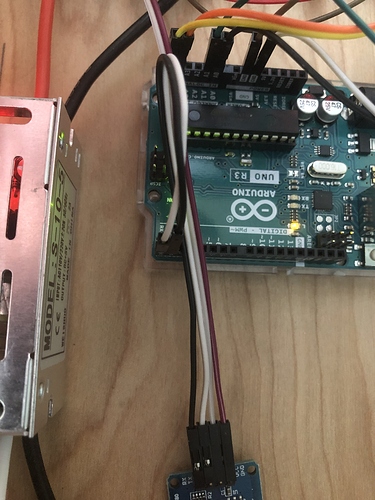

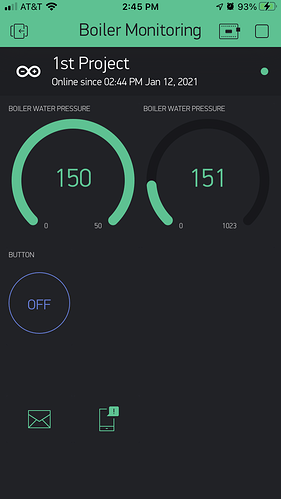

I’m working on a project where the goal is to be able to monitor and shut down (if necessary) a hot water boiler using a PT100 rtd, a pressure sensor, and a conductance type low water level cutoff. I have an Arduino Uno, an i2C lcd, and an ESP8266. Initially I got the code working to just display onto the physical lcd hardware. I also verified with some simple code that the ESP8266 is working correctly and able to communicate with the Blynk app. All devices are externally powered, and do not draw on the Arduino source.

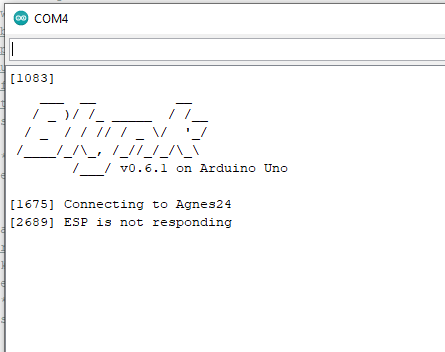

Next, I started integrating the code to work with Blynk so I can also monitor the values shown on the lcd on my phone as well. When I added the Blynk code, the lcd now stops showing anything, and continually reboots. Also, Blynk shows that the ESP8266 is continually going on and offline.

I looked all around the Blynk site and others to try to piece together a solution for this problem, but all examples appear to be just different enough to solve my specific problem. Also, I’m just learning how to code, so I’m learning as I go.

Any help in identifying where my code is problematic is greatly appreciated.

Thanks.

/*

The following functions are included within this program

Monitor P100 RTD

Reads an analog input on pin 0, converts it to voltage, and prints the result to a LCD Screen.

This example code is in the public domain.

http://www.arduino.cc/en/Tutorial/ReadAnalogVoltage

Monitor Pressure Transducer

Uses a standard 3-wire pressure transducer and reads the analog signal, then converts the signal to a

readable output and displays it onto a LCD screen.

Monitor Low Water

Using a GuradDog RB-24E conductance type low water cut-off switch, the device is powered by the

24V DC power supply. The 'pass-through' yellow leads of the device normally pass the 24V DC supply

through to the boiler to power it when the sensor senses water. In this case, the leads will be

connected to a 24V DC to 5V DC step down regulator. The regulator will normally supply 5V DC to the

Arduino when the RB-24E senses water. When the RB-24E does not sense water, the 5V supply will stop

supplying power to the Arduino. The Arduino will then signal a relay to interrupt the boiler

power supply.

Values are sent to Blynk App via ESP8266 WiFi Module

*/

#include <Wire.h> //includes outside library allowing communication over i2c devices

#include <LiquidCrystal_I2C.h> //includes outside library allowing interfacing with LCD screens

#include <math.h> //mathematical functions for manipulating floating-point numbers

#include <ESP8266_Lib.h> //ESP8266 interface library

#include <BlynkSimpleShieldEsp8266.h> //Blynk interface with ESP8266

//Blynk communication variables

#define ESP8266_Baud 115200 //constant to set baud rate for the ESP8266 module

#define BLYNK_PRINT Serial //redirects built-in status prints like ASCII logo and time stamped messages to serial monitor

//pressure measurement variables

float pressureInput = A1; //select the proper analog input pin for the 3-wire pressure transducer

const float pressureZero = 99.5; //analog reading of pressure transducer at 0 psi

const float pressureMax = 929.775; //analog reading of pressure transducer at 150 psi

const int pressureTransducerMaxPSI = 150; //maximum pressure rating of transducer being used.

float pressureValue = 0; //variable to store the pressure value calculated from analog value

//temperature measurement variables

float tempInput = A0; // select the proper analog input pin for the P100 RTD

const int tempMax = 1023; //analog reading of PT100 RTD at 572 deg F

const float tempVoltageMax = 5.0; //constant set to the maximum voltage reading of P100 RTD

const int tempMaxDeg = 392; //constant set to the maximum temperature reading of the transmitter in deg F

const int tempMinDeg = 0; //constant set to the minimum temperature reading of the transmitter in deg F

float tempValue = 0; //variable to store the temperature value calculated from analog value

float tempVoltage = 0; //variable to store the calculated voltage

float round_tempValue = 0; //variable to store rounded tempValue

//GuardDog RB-24E monitoring Variables

int voltageInput = A2; //select the proper analog input pin for 5V

//display variables

const int baudRate = 9600; //constant to set the baud rate for the serial monitor

const int sensorReadDelay = 1000; //constant integer to set the sensor read delay in milliseconds

const int pressDisplayDelay = 500; //constant integer to set the pressure status message read delay in milliseconds

const int tempDisplayDelay = 1500; //constant integer to set the temperature status message read delay in milliseconds

const int lwcoDisplayDelay = 2500; //constant integer to set the low water cut-off status message read delay in milliseconds

//digital output to control relay

const int digOutPin = 7; //Assigns the digital output pin beting used to actuate relay

//Blynk code to communicate with ESP8266 and Blynk app

char auth[] = ""; //auth code given by Blynk app

// Your WiFi credentials.

// Set password to "" for open networks.

char ssid[] = "";

char pass[] = "";

//use Software Serial on Uno, Nano...

#include <SoftwareSerial.h>

SoftwareSerial EspSerial(2, 3); // RX, TX

ESP8266 wifi(&Serial);

LiquidCrystal_I2C lcd(0x27, 20, 4); //sets the LCD I2C communication address: format(address, columns, rows)

BlynkTimer timer;

//function sends Arduino's up-time every second to Virtual Pin

//in app, Widget's reading frequency should be set to PUSH. This means that you define how often to send data to Blynk app

void myTimerEvent1()

{

Blynk.virtualWrite(V5, pressureValue);

}

void myTimerEvent2()

{

Blynk.virtualWrite(V6, tempVoltage);

}

void myTimerEvent3()

{

Blynk.virtualWrite(V7, round_tempValue);

}

void myTimerEvent4()

{

Blynk.virtualWrite(V8, voltageInput);

}

//the setup routine runs once when reset is pressed:

void setup()

{

Serial.begin(baudRate); //initializes serial communication at selected baud rate bits per second

delay(10);

lcd.init(); //initializes the LCD screen

lcd.init(); //initialized the LCD screen

lcd.backlight(); //initializes the LCD backlight

pinMode(digOutPin, OUTPUT); //the assigned pin will control the relay with an output

digitalWrite(digOutPin, HIGH); //relay will be activated interrupting power to boiler when pin is LOW

//Blynk code to communicate with ESP8266 and Blynk app

Serial.begin(ESP8266_Baud);

delay(10);

Blynk.begin(auth, wifi, ssid, pass);

//setup a function to be called every second

timer.setInterval(1000L, myTimerEvent1);

timer.setInterval(1000L, myTimerEvent2);

timer.setInterval(1000L, myTimerEvent3);

timer.setInterval(1000L, myTimerEvent4);

}

//the void loop routine runs over and over again forever:

void loop()

{

//the following applies only to monitoring the pressure transducer

pressureValue = analogRead(pressureInput); //reads value from the input pin and assigns a variable

pressureValue = ((pressureValue - pressureZero) * pressureTransducerMaxPSI) / (pressureMax - pressureZero); // conversion equation to convert analog reading to psi

Serial.print(pressureValue, 1); //prints value from previous line to serial

lcd.setCursor(0,2); //sets cursor to column 0, row 2

lcd.print("Press.: "); //prints label

lcd.print(pressureValue, 1); //prints pressure value to LCD screen, 1 digit on float

lcd.print(" psig"); //prints label after value

lcd.print(" "); //to clear the display after large values or negatives

delay(sensorReadDelay); //delay in milliseconds between read values

//the following logic changes display and controls relay based on pressure conditions

if (pressureValue >= 28) {

digitalWrite(digOutPin, LOW); //activates relay, interrupting power to boiler

lcd.setCursor(0,3);

lcd.print("Pressure Too High!! "); //prints label

delay(pressDisplayDelay);

}

else if (pressureValue <= 10) {

digitalWrite(digOutPin, LOW); //activates relay, interrupting power to boiler

lcd.setCursor(0,3);

lcd.print("Pressure Too Low!! "); //prints label

delay(pressDisplayDelay);

}

else {

lcd.setCursor(0,3);

lcd.print("System Press. Normal");

delay(pressDisplayDelay);

}

//the following applies only to monitoring the P100 RTD

tempValue = analogRead(tempInput); //reads value from the input pin and assigns a variable

tempVoltage = tempValue * (tempVoltageMax / tempMax); //calculated voltage

tempValue = (93.867 * ((tempValue * (tempVoltageMax / tempMax))) - 65.707) + 1.041; //converts the analog reading to deg F

round_tempValue = roundf(tempValue * 1000); //rounding to 3 decimal places

round_tempValue = round_tempValue / 1000;

Serial.print(tempValue, 1); //prints value from previous line to serial

lcd.setCursor(0,0); //sets cursor to column 0, row 0

lcd.print("Temp.: "); //prints label

lcd.print(round_tempValue, 0); //prints temperature value to LCD screen, 0 digits on float

lcd.print(" "); //prints space after value

lcd.print((char)223); //prints degree symbol after space

lcd.print("F"); //prints F after degree symbol

lcd.print(" "); //to clear display after large values or negatives

delay(sensorReadDelay); //delay in milliseconds between read values

Serial.print(tempVoltage, 1); //prints value from voltage calculation to serial

lcd.setCursor(0,1); //sets cursor to column 0, row 1

lcd.print("Temp.V.:"); //prints label

lcd.print(tempVoltage, 3); //prints voltage value to LCD screen, 3 digits on float

lcd.print(" volts"); //prints label after value

lcd.print(" "); //to clear display after large values or negatives

delay(sensorReadDelay); //delay in milliseconds between read values

//the following logic changes display and controls relay based on temperature conditions

if (tempValue >= 250) {

digitalWrite(digOutPin, LOW); //activates relay, interrupting power to boiler

lcd.setCursor(0,3);

lcd.print("Temp. Too High!! "); //prints label

delay(tempDisplayDelay);

}

else if (tempValue <= 45) {

lcd.setCursor(0,3);

lcd.print("Temp. Too Low!! "); //prints label

delay(tempDisplayDelay);

}

else {

lcd.setCursor(0,3);

lcd.print("System Temp. Normal ");

delay(tempDisplayDelay);

}

//the following applies only to monitoring the GuardDog RB-24E

if (voltageInput <= 1000) {

digitalWrite(digOutPin, LOW); //activates relay, interrupting power to boiler

lcd.setCursor(0,3);

lcd.print("LowH2OLvl Detected!!"); //prints label

delay(lwcoDisplayDelay);

}

else {

lcd.setCursor(0,3);

lcd.print("Water Level OK "); //prints label

delay(lwcoDisplayDelay);

}

//Blynk code to communicate with ESP8266 and Blynk app

Blynk.run(); //initiates Blynk

timer.run(); //initiates BlynkTimer

}