I found the problem. was my severals nodeMCU connected on my computer at the same time!!! OMG! so many ports, and I was uploading the code to the wrong nodemcu…

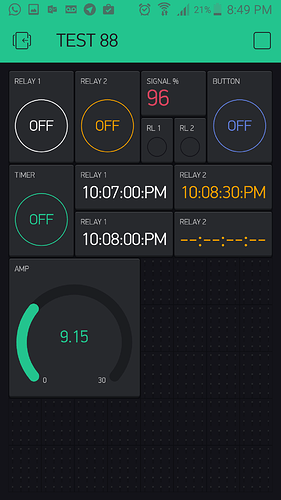

I did the code. the loop ask the read function using SimpleTimer, 1 time per second and send the value to the blynk on V13 I used a GAUGE widget.

#define BLYNK_PRINT Serial // Comment this out to disable prints and save space

#include <ESP8266WiFi.h>

#include <BlynkSimpleEsp8266.h>

#include <SimpleTimer.h>

char auth[] = "...";

char ssid[] = "....";

char password[] = "...";

const int sensorIn = A0;

int mVperAmp = 66; // use 100 for 20A Module and 66 for 30A Module

double Voltage = 0;

double VRMS = 0;

double AmpsRMS = 0;

SimpleTimer timer0;

void readACS712() {

Voltage = getVPP();

VRMS = (Voltage/2.0) *0.707;

AmpsRMS = (VRMS * 1000)/mVperAmp;

Serial.print(AmpsRMS);

Serial.println(" Amps RMS");

Blynk.virtualWrite(V13, AmpsRMS);

pinMode(sensorIn, INPUT);

}

void setup(){

Serial.begin(9600);

Blynk.begin(auth, ssid, password);

timer0.setInterval(1000L, readACS712);

}

void loop(){

Blynk.run();

timer0.run();

}

float getVPP()

{

float result;

int readValue; //value read from the sensor

int maxValue = 0; // store max value here

int minValue = 1024; // store min value here

uint32_t start_time = millis();

while((millis()-start_time) < 1000) //sample for 1 Sec

{

readValue = analogRead(sensorIn);

// see if you have a new maxValue

if (readValue > maxValue)

{

/*record the maximum sensor value*/

maxValue = readValue;

}

if (readValue < minValue)

{

/*record the maximum sensor value*/

minValue = readValue;

}

}

// Subtract min from max

result = ((maxValue - minValue) * 5.0)/1024.0;

return result;

}