when it’s disconnected it show´s 999,9 in serial Monitor. At the moment i only testing it over serial output

are you sure the probe is K-type?

Yes, I am sure. Have another BBQ thermometer. This is called “Wlan Thermometer” http://wlanthermo.com/

On this thermometer I use 4 Ikea Fantast probes and 2 TYP-K termoelements on an AD595 signal converter. And so they work without problems.

Great , clean and beautiful make .well done.

i feel your pain, i got 5 more MAX31855 to experiment with, mostly in my wood heater project,

but all five are failing to work like the Adafruit copies.

it is this style i am trying:

very disappointing.

Can you please post it image Blynk project clone QR code? Thanks

Dave,

I love your idea…!! Just bought a Kamodo Akorn Smoker, and am looking to do some temperature control. I have never used Blynk, but I love your app.!! I see you are currently working on just monitoring…but I would like to add a servo and fan to control my temperatures. I see your monitoring code, and am planning on studying it and then adding in the PID code for control. Can you post the Blynk code as well…

Thanks!

Steve

Dave…are you still checking this thread…? If so, can you reply to let us know as to whether you will post your Blynk Code…? I almost have all my parts, and was wanting to get started this weekend. Can you post it…? Love your screens.

Thanks in Advanced.

Steve

not what you mean by “blynk code”?

there’s heaps of blynk code in post #1

Sorry Dave. Still learning the terminology. The arduino code is great! Thanks!! I was asking for the blynk QR, to use your app as a starting point. Did I miss it somewhere? I am new to the blynk stuff.

Yes…!! Thanks so much…what a great starting point.

Fantastic work, Dave.!

that is for the chip itself not the breakout board.

Dave,

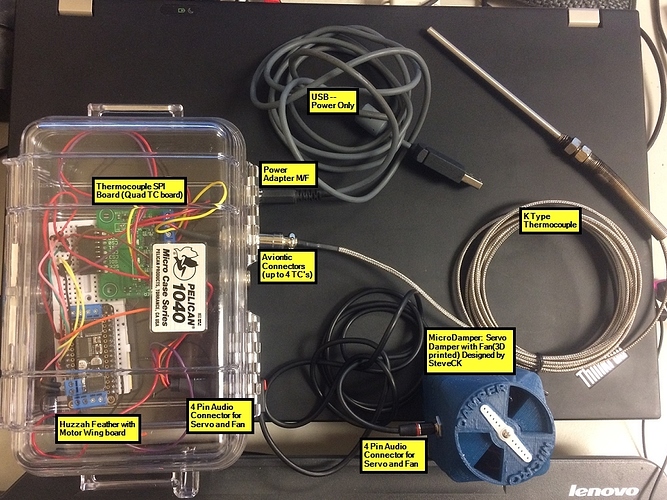

Am working hard on my version of your BBQ monitor…which adds 4 probes capability and a Servo Damper and Fan for temperature control. I have most of it working…but I haven’t been able to find a good way to get the TC’s into the enclosure. Where did you get the connectors for the TC’s and the Power Supply input…? That is my last piece of the puzzle, and then I start to pull them all into one glorious BBQ controller.!!

Thanks for all your help.!!

Steve

i got everything from ebay =

connections i use:

“Aviation Plug GX12 3pin”

probes you type in:

“k-probe stainless”

PSU search for a “2.5mm DC” use a “metal” one for the female chassis connector…

Thanks Dave…! I ordered a 10 pack of the 12mm connectors. Do you have any issues with the connector being between the TC cable and the TC circuit board…? Wasn’t sure if that might mess with the TC reading a bit, due to it not being dissimilar metals…like it might make an additional TC junction and make the ambient temperature add to your readings. I definitely hadn’t found anything for K TC’s except for standard panel mount plugs…but nothing waterproof like yours.

Got the Fan and Servo Damper working on the bench…so when these come in, it will be time to assemble and give it a whirl.

Did you make a template for your enclosure…? Is that just a hobby box with a clear lid that you mounted the LCD on…? With a paper cutout to block the view of the electronics…?

Not sure I am adding an OLED or not…with the Blynk software, I just use my phone.

Thanks again for your help.

Steve

Hi @Dave,

Fort an ideal cooking point it’s needed to monitor the meet’s inner core temperature. Are you monitoring that and if so, how since the skewer is rotating?

I monitor the time and check internal temp periodically towards the end of the cook, the rotisserie has an on/off switch…

no

BUT i do sometimes notice if the thin meat probe touches the BBQ or the main TC probe it can send an error reading, so like on Ghost Busters - do NOT cross the streams…

i think the junction is at the tip, everything past that is just wire.

i made them up myself, using GX12 plugs.

the wire from the probe is not very easy to solder, so you have to hook it into the GX12 plug connections and be very meticulous.

err, no, i just drill & stuff it all in.

get a “step drill” these are great to use with the plastic boxes.

it was about $1.17 from eBay

no, i used some left over spray enamel and spray teh inside of the clear plastic, take a closer look ![]()

around here, there are a few people that get trusted with BBQ duties, so that is why it has the OLED that scrolls through all the readings…

because if i am doing other stuff, they can resist the temptation to lift the lid to check the meat (a big no-no!)

keep it up ![]()

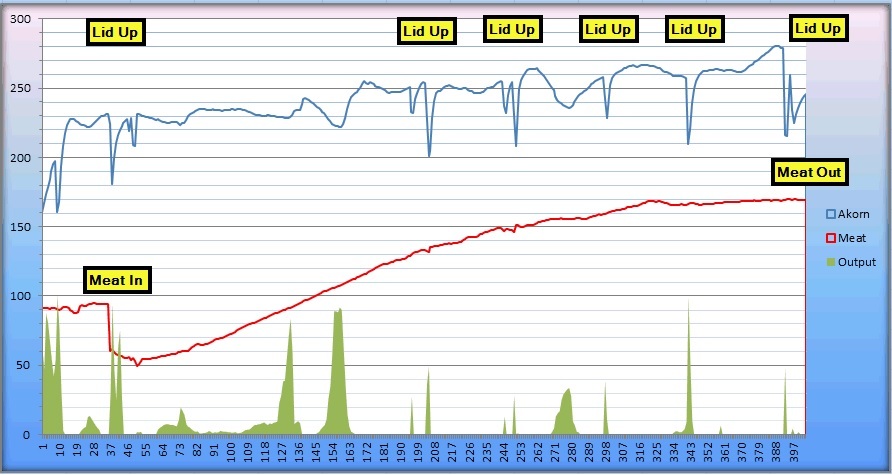

Dave,

I got it working…!! I haven’t added in my local OLED Display, but with the iPhone Blynk App and the Android App(in an emulator) running on my phone and Laptop, I really didn’t need the local display. This was my first run, and I forgot to program in the Lid Up routine to shut off the PID loop, when the micro determines that the lid was lifted. That made my fan blow on the coals and the heat got away from me a bit…but that is easily fixed. Thanks for all your help getting me started…I have used a bit of your code, but have revamped it to have 4 K-thermocouples and of course the PID with Servo Damper and fan blower. I attached a pic of my controller on my desk and the Output graph of the cook.

Thanks again…!

Steve